SAMSUNG PANEL

THE SAMSUNG PANEL TYPE WATER TANK

KEEPS WATER COLD

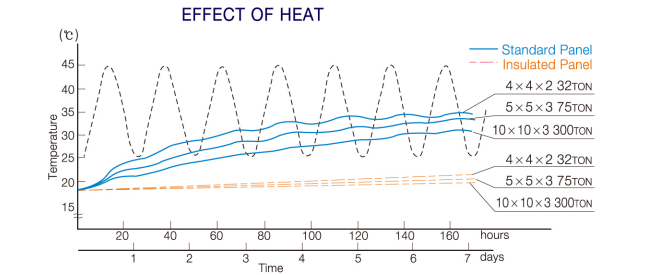

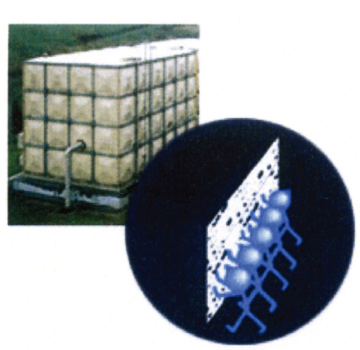

Glass fiber reinforced plastic has a very low thermal conductivity. The actual value is approximately 1/240th of the value for steel A typical problem with steel tanks has always been the high thermal conductivity and expansion coefficient of steel. These characteristics can cause loosening of the panel connecting bolts in areas of wide temperature change. GRP panels,however, are not affected to such a high degree. Thus, the water stored in GRP panel tanks will not reach the high temperatures to which the outside of the tank is exposed in semi-tropical or tropical zones. SAMSUNG has successfully developed specially insulated panels to meet the temperature extremes of tropical or arctic regions and has conducted a wide range of tests at both the high and low temperature levels.

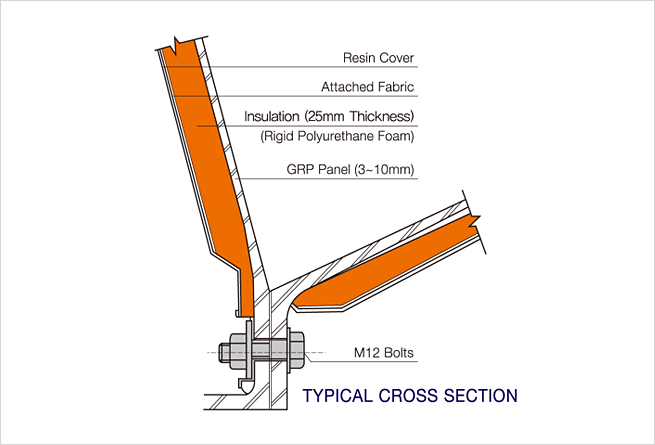

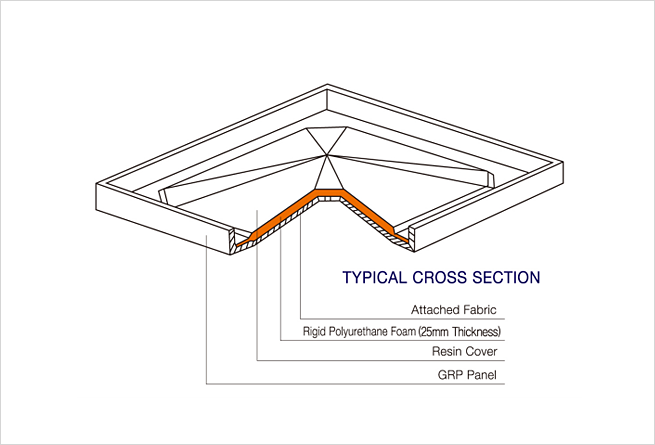

STRUCTURE OF HEAT INSULATED PANEL

The SAMSUNG insulated panel has specially developed low thermal conductive rigid polyurethane foam, fabric in between GRP single panel and GRP cover as shown below. These panels`are used for the side and bottom and roof of the tanks. Since an air layer exists between the roof and the water level,which itself acts as a thermal insulation, single panels are used for the roof. Other company's insulate panel cannot endue by high temperature. But SAMSUNG panel used inside fabric for strong adhesion panel and polyurethan foam.

THERMAL CONDUCTIVITY

| Thermal Conductivity Kcal/m.hr° (J/m hr° C) | |

|---|---|

| STEEL | 37.0 (1.55 105) |

| GRP (Standard) | 0.15 (630) |

| GRP (Insulated) | 0.02 (84) |

GRP Panel's Physical Properties / Basis on KS F 4811)

| 1) Tensile Strength | 850kg/cm2 |

|---|---|

| 2) Flexural Strength | BS 2782 Part 10 Method |

| 3) Flexural Modulus | 12.0 GPa |

| 4) Water Absorption Rate | < 0.20 % |

| 5) Barcol Hardness | Over 40 |

| 6) Glass Fiber Content | > 30 % |

Material Characteristics and specification

| 1) Specific Gravity | 1.7 - 1.8 |

|---|---|

| 2) Impact Strength | 75kg/cm2 |

| 3) Shore Hardness | D90 |

| 4) Shear Strength | 830KG/CM2 |

| 5) Thermal Expansion | 2.1 x 10-5 ASTM D 696 - 79 |

| 6) Thermal Conductivity | 0.15 kcal/m.hr C BS 874 part2 - 1986 Sec.2.1 |

| 7) Overall Heat Transmission | 0.6 W/M2K |

| 8) Light Transmission | BS 2782 : Part 11 Method 11043 |

| 9) Insulation Thickness | 25 mm PUF |

| 10) Insulation Cover Material | ABS OR PE |

FEM

Safe and robust panel construction is designed considering the stress

concentration on the panel when load is applied by FEM.

High Quality Water Tank

We always ensure all safety requirements such as strength, durability and stability with rigid design regulation and quality control

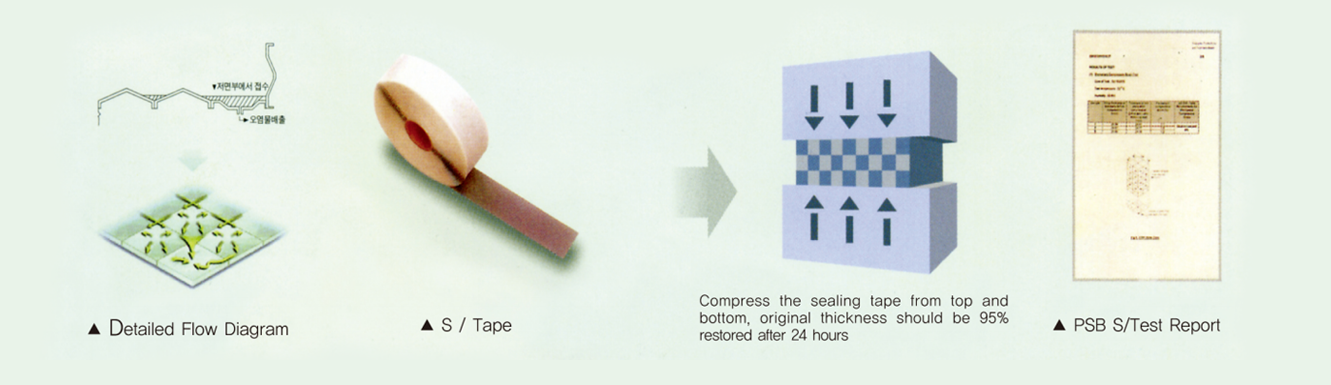

SPECIAL SEALING TAPE FOR WATER TIGHT JOINTS / BOTTOM DRAIN SYSTEM

- - Specially developed sealing tape ensure leakage free water tank.

- - The dome shaped bottom panel with a concave drain panel facilitates complete and quick drainage.

SAMSUNG GRP SECTIONAL WATER TANK TECHNICAL DATA

MATERIAL

A. The hot pressed Glass Reinforced Plastic (GRP) shall conform to the following strength:

| Specific Gravity | 1.8 |

|---|---|

| Minimum Tensile Strength |

850 Kg/cm2 |

| Minimum Impact Strength | 75 Kg/cm2 |

| Minimum Shear Strength | 830 Kg/cm2 |

| Thermal Conductivity | 0.15 kcal/m.hr.℃ |

| Thermal Expansion per C |

2.1 x 10-5 |

| Bottom panel max. thickness | not less than 6 mm |

| Side panel max. thickness | not less than 6 mm |

| Sealing materials | special EVA sealant |

| Glass content | 30%+ according to BS2782 part 10 method 1002 |

| Water absorpation | according to BS 874 part 2-1986 Sec 2.1 ( < 0.20% ) |

| Light transmission | BS 2782 part method 11043 (nil) f Factor 0% |

| U.V.Radiation | BS 2782 part 5 method 552A-1981 |

| Soaking microbiologist chemical resistance | BS 6920 part 1-1988-nil 0% |

B. The Stainless Steel shall conform to BS-970 grade 316/L.(option)

-

PANELS AND FLANGES

The panels, brackets, corner angles and pads etc., was made of GRP. The panels was made by hot pre/press moulding process. The flanges of the panels shall be externally moulded square to the face of the panel with extra reinforcement and free from irregularities. Similar panels shall be inter-changeable convex panels shall be used for the bottom(floor) of the tank.

-

ROOF COVER

The tank shall be provided with a heavy duty cover/roof constructed from Standard "GRP" tank panels, bolted and sealed as the tank is built and supported from the base of the tank with "GRP" tubualr or stainless steel struts.

-

SEALING MATERIAL, NUTS & BOLTS

The sealing material is "Special EVA Sealant" of thickness suitable to withstand the water quality and the extreme weather conditions. Bolts, nuts and washers used for assembling the panels shall be of Stainless (internal) However, bolts, nuts and washers not in contact with water can be dipped galvanized conforming to BS-729.

-

EXTERNAL BASE SUPPORT

The external support frames, bracings, plates, corner angles, etc HDG Steel Sections

-

INTERNAL REINFORCING

The sides and ends of the tank is reinforced internally with stays, ties and diagonal struts to provide strength and stability to the tank. The stays, ties and struts, washers nuts and bolts, etc shall be made from stainless steel grade 316L. (option)

-

ACCESSORIES

The tank is accessories as under.

A. A hinged manhole cover with a 60x60 cm. opening and sealed lid.

B. Access ladders:

Inside the tank - GRP or stainless steel ladder

Outside the tank - HDG Galvanized Steel ladder

C. Screened Air Vents.

D. Level Indicator (big size) to show water level from outside.

(outside Aluminium case cover)

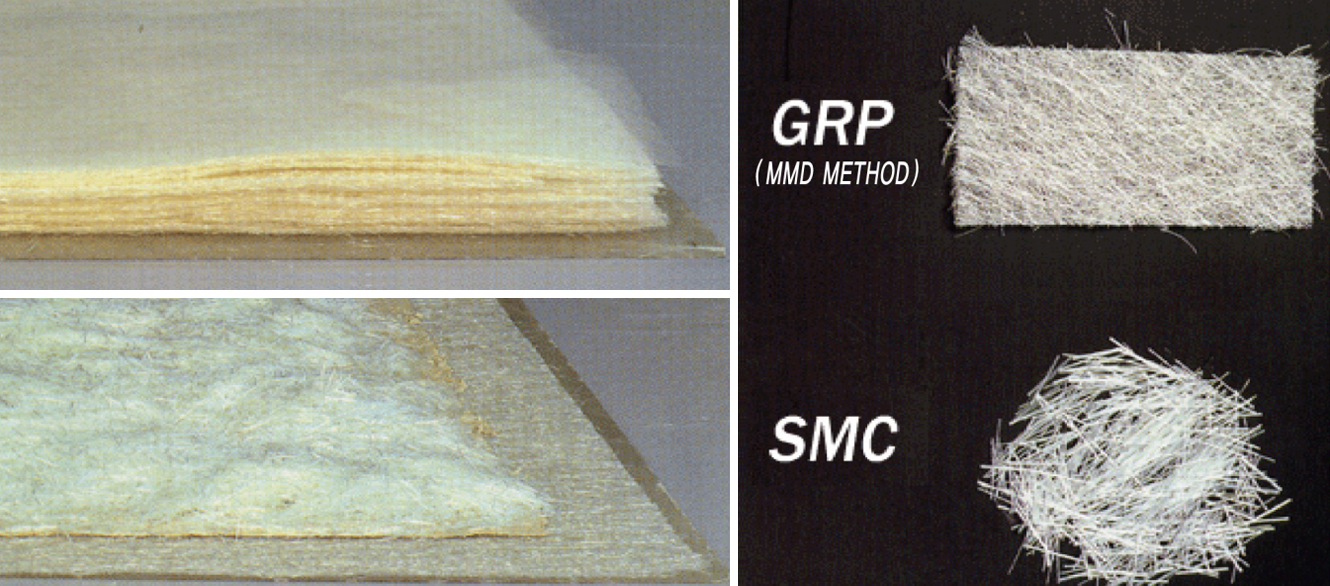

The Advantages Of The SAMSUNG MMD Panel Manufacturing Method

MMD Method

Uses long continuous filament fibre for extremely high strength!

Panel Uses

Uses suitable for high water pressure!

Highly suitable for water storage.

SMC Method

Uses short-strand fibre which gives rise to questions regarding strength!

Suitable

for low water pressure applications!

Suitable for bathtubs (depth of 0.3m - 0.5m) and other items that only need to bear the weight of a single individual, such as chairs and the like.

Comparison Specifications

| Tensile Strength | |

| MMD / SAMSUNG MCP | 85 - 105MPa |

| SMC / Other Korea Company | 58.8 - 100MPa |

| Hand Layup Company / Dubai, UAE | 39.2 - 68.6MPa |

* Note : SAMSUNG MCP tanks attain Singapore Standard "SS245" at 6 times working pressure under hydrostatic pressure tests.

SAMSUNG Panel Tank manufacturing Technology

There are 2 basic methods for the manufacture of panel tanks : GRP and SMC

SAMSUNG utilises its exclusive MMD method. The MMD method introduced by SAMSUNG and it continues to be the most superior method of manufacturing today.

On the other hand, other manufacturers employ the SMC method. The difference between these two methods is that the MMD method uses long continuous strand fibreglass, adding resin and then submitting the mixture to pressure before the final moulding process. The SMC method used by all other panel tank manufacturers mixes short-chopped strand fibreglass and resin in a "clay-like" mixture.

In terms of product characteristic, this means that panels manufactured under our GRP method are not only thinner and lighter, but the long continuous strand fibreglass maked them a product for superior in strength to all others. Through our hot press moulding method, stability in product quality is asured even high volume production.

Physical property Comparison

| SAMSUNG | Other Company | Hand lay-up | Comparison | |

|---|---|---|---|---|

| GRP (MMD) | SMC | company B | ||

| Tensile strength (MPa) |

85~105 | 58.8~100 | 39.2~68.6 | GRP tanks(MMD Method) attain Singapore Standard "SS245" at 6 times working pressure under hydrostatic pressure tests. |

| Bending strength (MPa) |

170~220 | 117.6~161.7 | 64.2~156.8 | Other companies' products are harder, containing about 40% filler, negatively influencing both impact and repetition strength tests. |

| Water absorption coefficient |

Below 0.2% | Over 0.3% | 0.20.3% | The superiority of the initial strength of GRP products is additionally evident in its durability over the long term. |

The Different Fibreglass Using in Panel Tanks