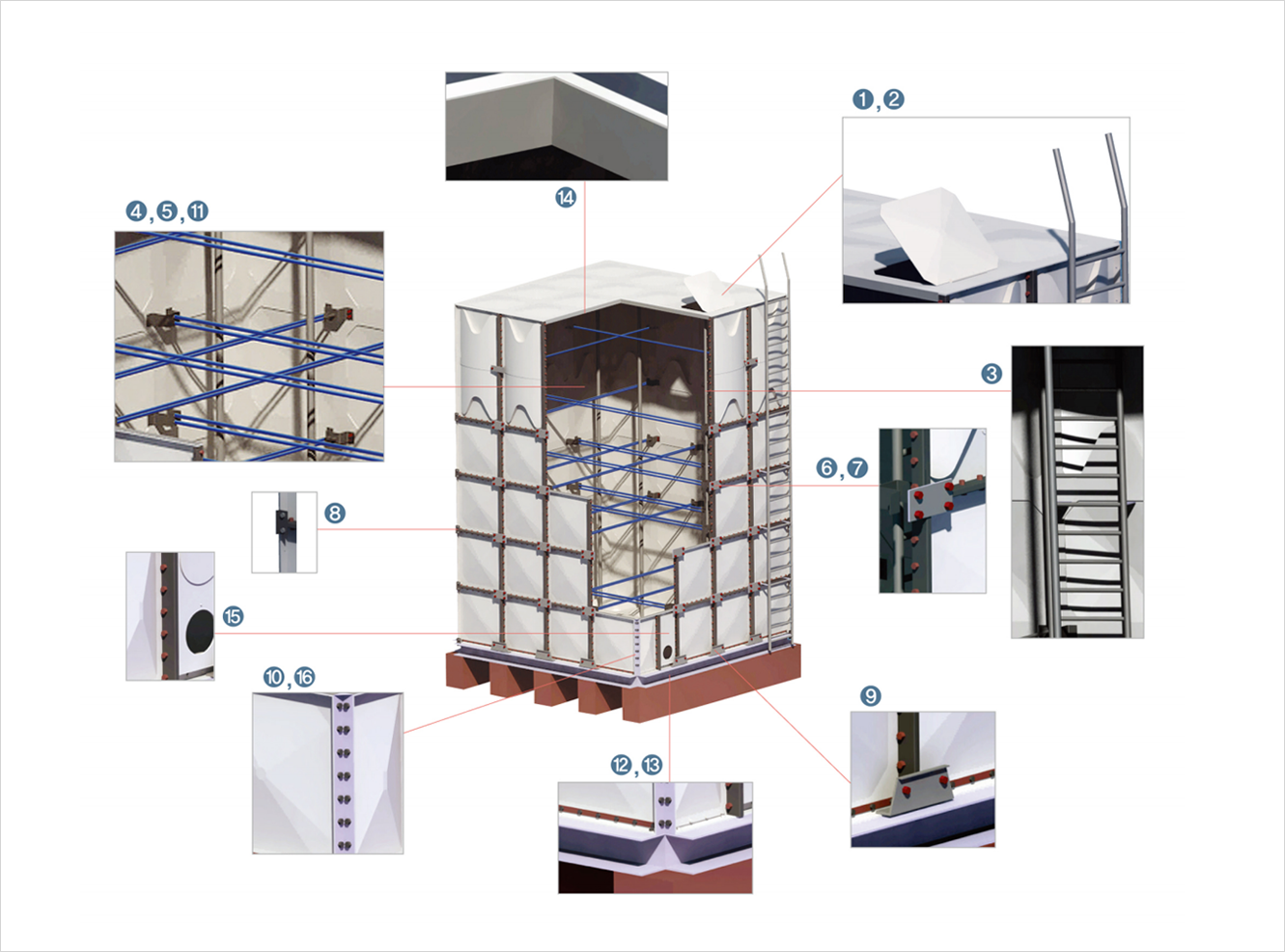

Internally Reinforced

Internally Reinforced System

- - It is possible that various capacity's design and flexible space should be used by GRP panels standardized

- - Excellent watertightness, hygienic conditions and non-leakage applied internally reinforced stay(Stainless)

| No. | Name | Material | No. | Name | Material |

|---|---|---|---|---|---|

| 1. | Manhole panel | GRP | 11. | Roof support pipe | GRP |

| 2. | External ladder | SS41(HDG) | 12. | Base frame | SS41 (HDG) |

| 3. | Internal ladder | GRP | 13. | Bolts and Nuts | Inside:STS304 or 316, Zinc Plated+ PVC cap(Roof Panel) |

| 4. | Internal Tie Rod | STS 304(PET tube coating) or STS 316 | Outside : Zinc Plated Steel + PVC cap | ||

| 5. | Internal bracket | STS 304(epoxy coating) or STS 316 | Connection : Rubber Cap + Zinc Plated | ||

| 6. | External reinforced bar | SS41(HDG) | Size : M10,12,14 | ||

| 7. | External bracket | SS41(HDG, Fixing cross part) | 14. | Sealing Tape | EVA or PVC Foam (Maintain water_proof with flexibility) |

| 8. | Corner bracket | SS41(HDG) | 15. | Water inspection window | GRP |

| 9. | Bottom bracket | SS41(HDG) | 16. | Panel | GRP |

| 10. | Corner frame | SS41(HDG) | * | STS 316 | Option Item |

Features of Internally Reinforced System

-

Excellent Hygienic Conditions

Minimized rust appearance of roof-sectional stainless parts inner Water Tank in accordance with basical options that are internally reinforced stays and brackets with epoxy coating.

Prevented rust appearance of Chlorine Gas through the assembly bolts added bolt-caps of roof section inner Water Tank -

Outstanding View

Prevented white peril or rust appearance through external assembly bolts added bolt-caps of Water Tank, and outstanding view

-

Easy to Assembly

Easy to assembly through internal and external optimized options of reinforced system.

-

Best Structure Stability

internally Reinforced System is verified structure stability of water tanks which have built in domestic and international sites for years.